Ecommerce Warehouse Layout: How to Design a Fulfillment Center

3 core principles for efficient eCommerce warehouse layout and how to maximize your storage space for improving your fulfillment process.

As a part of your overall warehouse layout design, the receiving and shipping areas are usually the first appointed, and one of the most important. When improperly laid out, the shipping and receiving process can negatively affect the entire warehouse. In this article, we will discuss the components of efficient receiving area layout to minimize any potential bottlenecks in warehouse operations.

Get A Quote – Tell Us About Your Receiving Area Requirements

A receiving area is a designated space in a warehouse where incoming goods are received and processed. This is usually called an “inbound” process.

Unless the primary type of warehouse is for cross-docking, the receiving area should be located as close to the storage area as possible. This helps minimize the distance goods have to travel for put-away. In a cross-docking setup, however, shipping and receiving should be located near each other.

Start With Our Warehouse Layout Guide

Have you read our guide about warehouse layout? If not, then jump over there first before following the steps below.

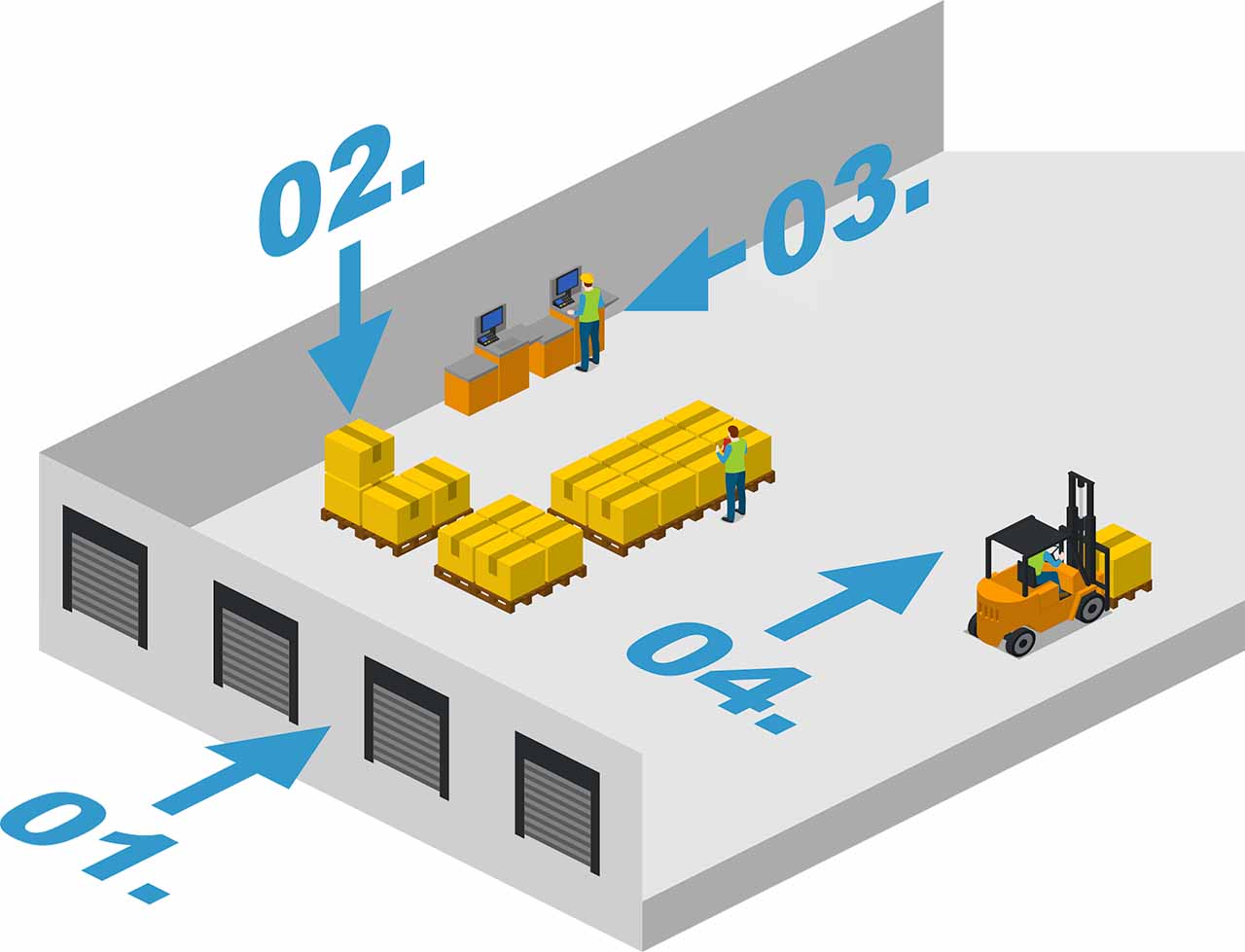

There are 4 main areas that occur in a receiving area. Here is how they usually break down:

Where inbound trucks connect to your warehouse.

Temporary storage for incoming materials.

Where inbound receipts enter in the inventory system.

Where handling equipment moves materials to storage.

A receiving area layout is important because it is the first place where goods can bottleneck in your warehouse. This can cause backups or other problems throughout the rest of the warehouse.

An efficient warehouse receiving layout allows goods to process quickly, safely, and with accuracy. Good accuracy minimizes costly errors, such as incorrect shipments or misplaced items.

Need help calculating usable warehouse space?

We have developed a simple tool that immediately calculates the total usable volume for you with some basic inputs.

To obtain an effective receiving area layout, 2 main considerations should be taken into consideration. By prioritizing these 2 considerations, you can create an effective receiving area layout that helps optimize warehouse operations.

The physical characteristics of the space include both the size and layout of the area, infrastructure, and any other features. The layout of the receiving area should allow for safe unloading and inspection of goods. Infrastructure needs include electrical outlets, IT and automation systems, and other necessary warehouse equipment such as forklifts or pallet jacks.

After the physical characteristics of the receiving area are clear, the mapping of material flow within the receiving area is next. The receiving process itself should be mapped out in detail so that workers know exactly where and what steps to take when receiving goods. During this process, the goal is to bottlenecks and unnecessary travel. For example, the staging area for inbound goods should be near (or next to) the docks, and also near the main storage area.

Now that you understand the importance of having an effective receiving area layout, let’s discuss how to design one. Here are some tips for creating an efficient receiving area:

To help understand how these principles work in an actual receiving area layout, we have put together a couple of examples to illustrate this. While there are many more kinds of examples we could examine, these two provide a basic overview of the core considerations to establish an efficient receiving process.

A brief glance at the example above and it’s plain to see that this layout has poor flow. A receiving area like this would suffer from heavy congestion and a high probability of safety issues. Here are the main concerns with this layout:

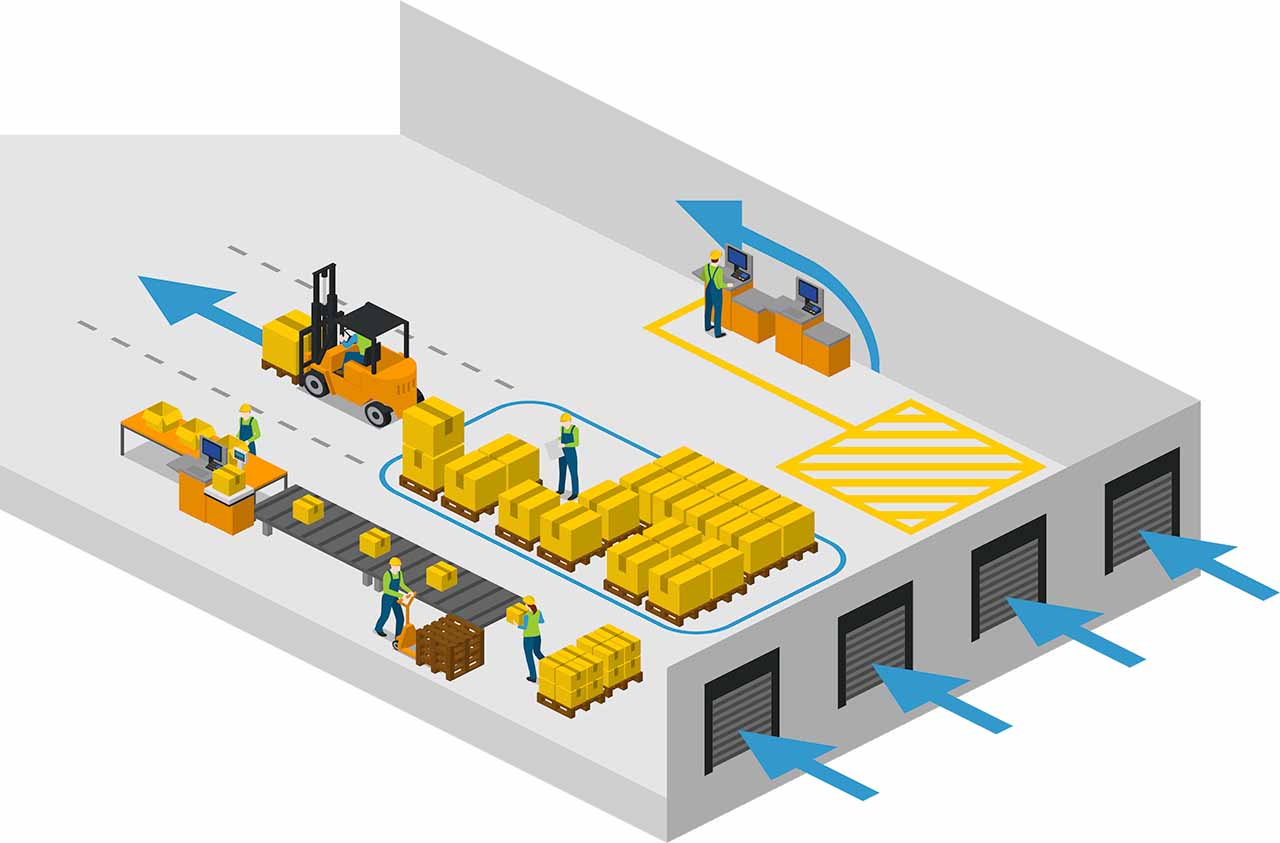

This example is much better, with clear lanes of traffic and flow that moves in one direction toward the rest of the warehouse. A receiving area design like this would minimize any bottlenecks that occur by simply altering the use of the space, and ensuring enough dock doors are present.

Since the receiving area is the first touch point of your entire warehouse operation, it’s best to consider it first in your warehouse layout. If you don’t, then the rest of your warehouse efficiency will suffer and costly problems will arise. You can use the principles in this article to help you plan ahead for your receiving area needs, and implement a design that will work for you.

3 core principles for efficient eCommerce warehouse layout and how to maximize your storage space for improving your fulfillment process.

Understanding eCommerce fulfillment – what it is, how it works, and how to optimize or outsource the process for your online business.

What is a fulfillment center and how does it differ from a distribution center? How do I decide which is right for my business?

There was a time when businesses revolved centrally around the customer and their needs. Decisions were made based on what is best for the customer first. People did what they said they would, and jobs were completed on time. AMS carries on the tradition of customer service today.

AMS is a customer service-centric warehousing and fulfillment company. We have the software, but we don’t replace PEOPLE and SERVICE with software. Being that we are a contract manufacturer as well, we have a lot of expertise and capability that you can rely on and trust.